Wishing to continue to compete with the big battery manufacturers in China, the United States and Korea, Japanese engineers must strive to find new technologies and materials.

The other end of the line for these calls are the companies that make cars and drones from Europe and the Americas. They look forward to working with 3Dom, a startup from Tokyo Metropolitan University in 2014.

At the start of development, 3Dom had only one employee and the only operator: Professor Kiyoshi Kanamura. But over time, as the good news spread, engineers from large companies like Panasonic also joined 3Dom; they are excited about the promise of a new breakthrough. Currently, 3Dom has a total of 70 engineers, nearly half of whom just joined about a year ago.

The rechargeable battery is one of the key points for Japan, but it is now competing with the Chinese and South Korean giants. In order to maintain their dominance in a market that could be worth up to $ 25 billion by 2035, Japanese engineers must do their best to keep up with rapid advances in technology; 3Dom plans to market its lithium batteries by 2022.

The startup claims that its batteries can produce twice as much energy as a Li-ion battery of the same size, whose power output has been widely proven. And yet, they say the battery charging ring will meet the needs of electric vehicles. 3Dom dreams even further, wishing that one day flying cars will use the batteries they produce.

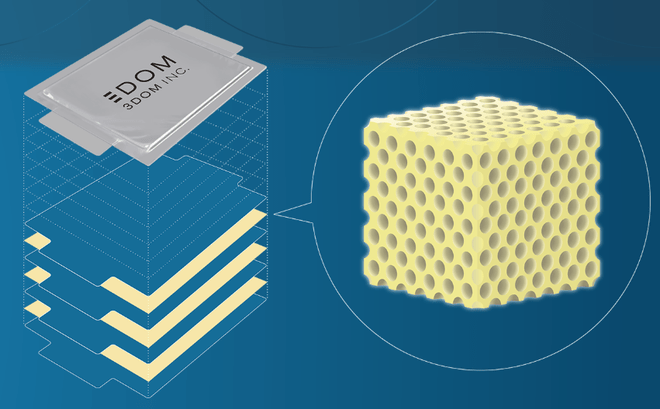

Most current Li-ion battery cathodes use carbon, but 3Dom chose lithium because of the benefit of storing more energy and reducing the risk of short circuits and fire. 3Dom has also found a way to counter dendrites – the lithium fibers found in “aged” Li-ion batteries, which can penetrate the barrier between the two poles and cause a short circuit: they create walls with holes. The circle measures several hundred nanometers, placed in the correct positions for a regular flow of ions and a regular chemical reaction.

This baffle is made of polyimide, a heat resistant plastic that does not burn even at temperatures up to 400 degrees C. Currently, 3Dom is making Li-ion batteries at a factory in Seattle and plans to build one. . another plant in the United States next year to prepare for new technology battery installation lines.

Great potential comes from small startups

As electric cars and electronics become more prevalent in the age of technology, the battery market will become more and more valuable. The top three groups, contemporary Chinese technology Amperex Technology (CATL), the world’s largest manufacturer of automotive batteries, followed by Panasonic and LG Chem in the next two positions, are both researching power sources. new generation.

The most potential technology currently is solid-state batteries which are safe and charge faster than existing batteries. Toyota Motor and Panasonic, two companies that collaborate on battery manufacturing with Tesla, are currently working on the technology.

Meanwhile, another startup called Azul Energy is not focusing on producing batteries, but is looking for a new material for batteries. Hiroshi Yabu, a materials scientist at Tohoku University, was inspired by a schoolboy and believes that the dye can become the catalyst used in batteries.

Mr. Yabu focused on a metal-to-air battery that uses oxygen as the reaction material for the anode and then metal for the cathode. This type of battery can store and discharge 3-10 times better than li-ion battery, but it can only output low current, not strong enough to run an automobile engine. Despite their excellent charge-discharge capacity, metal-air batteries are only used in hearing aids.

When Mr. Yabu used iron powder as a catalyst for the electrode instead of manganese, the electric current increased by 20 to 30 percent. It aims to strengthen metal-air batteries for use in drone drones.

Koju Ito, a former engineer at Fujifilm, is currently president and co-founder of Azul. Ito was skeptical when he accepted Yabu’s offer, but then took a new position by deciding “to enter a new hard-to-reach field while working at a large company.”

AC Biode, another energy start-up from Kyoto, has successfully developed rechargeable and discharged batteries with alternating current and not with direct current. Calling their new battery AC Battery, the AC Biode shows that their technology is 30% more flexible than a li-ion battery of the same size. In 2019, AC Biode received a significant investment from InnoEnergy, an organization that funds potential energy storage research projects.

Another startup, Connexx Systems, is developing a technology called Shuttle Battery, which generates electricity by mixing hydrogen and oxygen. Connexx’s battery generates hydrogen from powdered iron and water, then sends the hydrogen into an energy cell to produce electricity.

While startups have great growth potential and opportunities to break through, they have little potential to venture into the electric car industry dominated by energy companies and auto giants. According to market analyst Tang Jin, startups will need to partner with major battery makers as well as potential customers to survive this tough competition.

Nikkei