The name change doesn’t make Intel’s chips any faster, but it will make people think they’re not too slow compared to the competition.

A nanometer is a billionth of a meter, a thousand times smaller than the thickness of a human hair. It seemed like something so small wouldn’t matter, but no. This small size has become a huge problem for Intel.

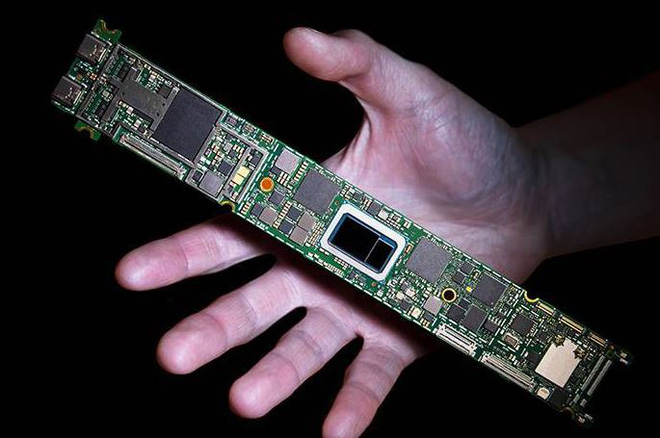

In the chip industry, “nanometers” are the size of the individual transistors inside the chip. The smaller the transistor, the denser the chip. The smaller transistors also mean that the chips can run at a faster speed, with less power, or a combination of the two.

And this term is also used to describe the manufacturing process technology used to make transistors – 65 nanometers, 45 nanometers, 32 nanometers … They are called technological nodes.

Every two years, Intel will switch to a smaller generation of chips. It also means that a manufacturer can put more computing power into the same chip. However, as the processes shrink with each generation, manufacturers have not been able to agree on what these numbers mean.

While Intel describes its most advanced microprocessor as the 10-nanometer generation, its rival TSMC is creating a competing product it calls a 7-nanometer process.

Few consumers think about it. When buying a laptop or smartphone, most don’t know if it’s powered by a 10nm, 7nm, or 5nm chip. In the semiconductor industry, however, the difference in numbers places Intel at a great disadvantage.

In most of the technical presentations, Intel’s engineers went to great lengths to make the point that their chips performed as well as their competitor’s products, which were described as being of the smallest generation.

Intel is now clearly tired of this argument.

According to recent sources, Ann Kelleher, who heads Intel’s technology development group, which focuses on the development of 5nm and 7nm process technologies, informed her staff that Intel has a plan to change the agreement to numbering to comply with industry standards.

It is not known when this will happen. Intel’s next generation of processors, now described as a 7nm chip, will debut in 2023.

Intel has declined to comment on its numbering plans at this time, except to reiterate that it believes its chip is more advanced than current descriptions.

“It is widely recognized in the industry that there is an inconsistency and confusion in the nomenclature of the nanometer and that it does not reflect the latest innovations at the transistor level,” said Intel spokeswoman Chelsea Hughes.

These differences in this regard are mainly scientific. Intel microprocessors have long been recognized as the most advanced in mass production, regardless of how many they choose to label them.

A series of manufacturing failures delayed three generations of Intel chips. TSMC, a contract manufacturer, started manufacturing 5nm chips in 2019 and has received a broad consensus that it is more advanced than anything Intel offers.

This is largely the reason why Apple moved its line of Macs away from Intel chips and switched to chips made by TSMC. And that’s why Intel’s rivals NVIDIA and AMD, both of which hire TSMC to produce their chips, are all grabbing market share in key segments that Intel has already dominated a long time ago.

Intel therefore seems to want to play the tag game.

It is not known what prompts Intel to change the numbering convention. However, new CEO Pat Gelsinger announced last month that Intel intends to compete directly with TSMC by seeking chip manufacturing contracts with other companies.

And Intel can hope to make it easier for potential customers to compare its products with TSMC by adopting a competitor’s numbering system. However, a different numbering system would be the easiest way.

But in the end, Intel has yet to demonstrate that it can reliably deliver new production technologies.

“We have already slowed down some transitions,” admits Gelsinger. “And without a doubt, we were no longer the leaders.”